In the world of modern architecture, innovative solutions are constantly pushing the boundaries of what is possible. One such revolutionary development is the Architen Lightframe, a modular fabric ceiling system designed to enhance the aesthetics, acoustics, and lighting of a space.

In the world of technical fabrics and tensile structures, architectural PVC polyester fabrics have played a pivotal role in transforming the way we design and construct buildings and outdoor spaces.

In the ever-evolving architectural landscape of the UK, the growth of tensile membrane structures has been part of a new era of innovation and design. Whilst traditional materials continue to be used, ETFE (Ethylene Tetrafluoroethylene) foil has become a key component in the construction of visually striking and environmentally friendly buildings, thanks to its lightweight and flexible nature.

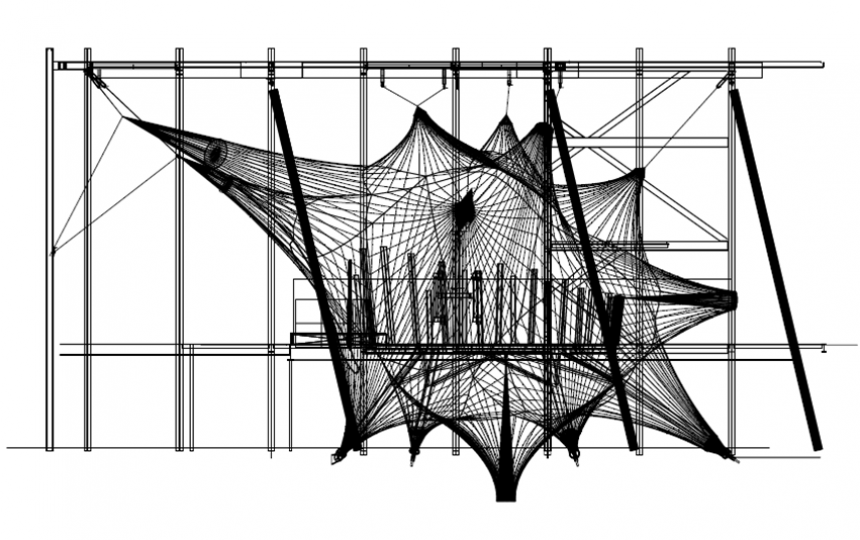

The installation of tensile structures is an art as much as it is a science. The complexities of tensioning membranes and cables to ensure perfect aesthetic and structural performance can only be understood by the experts.

Introduction:

ETFE or ethylene Tetra Fluoro Ethylene is now established as one of the most exciting materials in today’s design industry and architects, contractors and clients are becoming increasingly aware of the potential it offers.

So you have a brand new tensile fabric structure but how do you protect your investment and ensure that the structure reaches its full lifespan and remains looking as good as new? Step in the Architen Fabric Structures Maintenance Team! We’re here to offer you the full range of services to ensure that your membrane canopy continues to look and perform at its best.

Anti-Viral Membranes: Helping to Fight Coronavirus

Architen Landrell are excited to be able to offer a newly developed Anti-Viral and Anti-Bacterial membrane to help fight the spread of Coronaviruses and other winter germs. Developed by Serge Ferrari, the membrane is a major innovation as part of the fight against Coronaviruses.

Just like any piece of architecture, tensile fabric structures are built to meet a need at the time of construction, but what happens if the use of the building changes? Or an extension is built? Or a new owner wants to update the design?

Adapting and changing existing fabric structures is becoming more common as the lifespan of technical fabrics increases but it is a complicated process

We all know that one of the major benefits of using ETFE foil is its light transmission but what happens if it lets in too much light?

Fritting

In its clear form, a single layer of ETFE foil can transmit up to 85% of the light which hits its surface.

Much like a car, your ETFE cushion roof is dependent on all its parts working to ensure the safety and ongoing operation of the system. As a result, we recommend that every ETFE installation is serviced every 6 months. Our in-house Maintenance Team are some of the most knowledgeable in the word and look after structures in the UK and across the globe.

As a specialist in the design, manufacture and installation of ETFE cushion systems, we get asked questions about all aspects of the product, it’s uses, practicalities and benefits.

Two years ago we were putting the finishing touches on the one of the most recognised venues in the new Queen Elizabeth Olympic Park, the London Aquatics Centre. Through the financial support of Sport England, today, this venue has been transferred into a world class public swimming pool.

From yurts made of animal skins, to NASA space suits made of PTFE, fabrics have evolved and changed over time and yet all suffer from some form of environmental build-up.

Architen Landrell is excited to now be designing and manufacturing with the latest in fabric technology: PVC & PTFE fabrics coated with Titanium Dioxide (TiO2).

Introducing fabric to the inside of any space improves the acoustics, helps with solar glare, creates a feature and can be used to define a space. This article will walk you through the benefits of interior fabric applications.

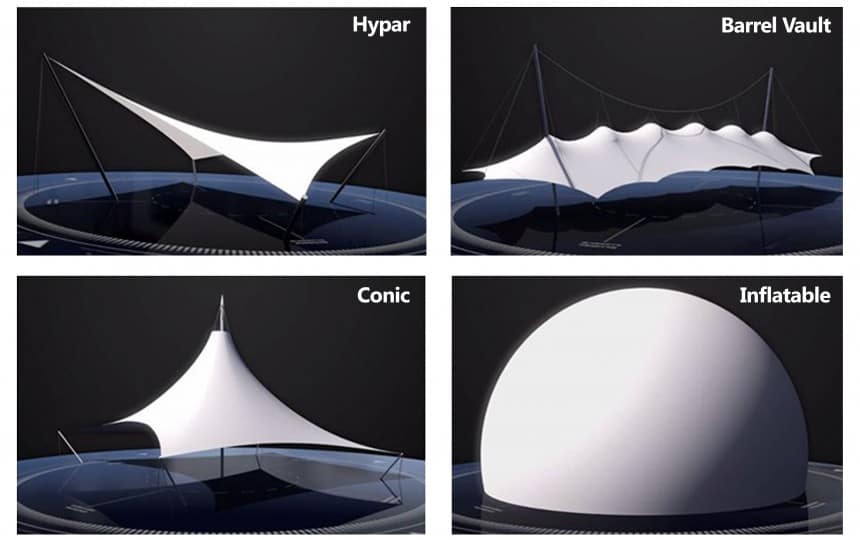

Fabric structures vary vastly from other forms of building materials. Their lightweight and versatility in shape and structure provides a unique range of dynamic and exciting three dimensional options.

Architen Landrell is pleased to offer a range of economically priced tensile fabric structures which are easy to specify and order. Below is a list of common questions we get asked about our Standard Structures.

What fabrics can I have?

We offer a choice of PVC coated polyester and silicone coated glass cloth for all of our structures.

Architen Landrell has worked in the industrial fabric industry for over thirty years and draws on this experience to offer a wide range of industrial services.

Adopting the same principles of project management, quality and customer service which we offer our architectural clients, Architen Landrell can provide anything from small repairs to large contract cutting and welding projects.

Brief: To design a feature entrance canopy for a company at the forefront of tensile fabric design demonstrating the uses of ETFE

Click on the download below to read the brief.

If you are looking for a cost-effective, quick and easy to install fabric feature in your space that looks great, then fabric sails are the best solution.

Want to inspire your students to fulfil their potential? Need to give your children a safe and dry place to play or work? How can canopies improve the educational experience at your school?

Stylish school canopies are perfect for providing playground shade, covered external classroom space or an effective walkway canopy between

One of the most exciting materials in the design industry Ethylene Tetra Fluoro Ethylene (ETFE) foil has set the construction world alight with the huge range of potential applications.

The most sought after building material of the moment, ETFE foil is a high translucency fabric which is extremely practical and economical.

Architen Landrell is currently responsible for the installation, subsequent striking, removal from site and storage of a number of tensile structures. All have unique characteristics regarding the type of structure, the installation methodology and the environment in which these structures are erected.

Membrane structures rely on double curvature to resist imposed loads efficiently.

Imagine a flat piece of fabric.

Introduction

This article describes Architen Landrell’s development of an acoustic liner for a building called Skyscape. This building was built on the Greenwich site in London as part of our Millennium celebrations and is one of the main attractions provided at the renowned Millennium Dome.

PTFE (Teflon) coated glass cloth has become established as the highest quality architectural membrane for tensile structures. The material was developed by DuPont in the 1960s and has been used for structures since the early 1970s.

This article will provide you with information on how tensile fabric structures perform in variety of conditions. Today’s fabric structures are built to last.

Wind

A frequently asked question is if tensiles are suitable for windy sites.

When architects and designers approach us with a tensile fabric structure idea, sometimes they know what type of fabric they want, other times, they look to us for direction. This article provides an overview on the fabrics we design & build with. Today’s fabrics are innovative, allowing you to create iconic spaces.

It’s now possible to have a beautifully shaped fabric roof while having it perform competitively against other materials, offering excellent U-Values.

Load Resolution

Canopies fall into two main types, those that transfer tensile loads into adjoining structures and those containing the tensile loads within their own frame. The first type may generate large lateral loads which may result in the need for additional in existing structures.

Introduction

Ethylene Tetra Fluoro Ethylene – not the sexiest of names, however ETFE foil is fast becoming one of the most exciting materials in todays design industry and has set the construction world alight with the potential it offers.